WES Industries allows its customers to capture waste heat already generated and convert it into clean energy. Waste heat recovery is recovering heat discharged as a byproduct of one process to provide the heat needed to produce energy for other processes.

Energy has always been a significant component of commercial and industrial operations, but only rarely has efficient energy use been a priority when developments were planned being planned. Maximizing energy use and minimizing pollution is more important than ever. Fortunately, a careful approach to energy adds profits to the bottom line and draws positive attention to the environmentally friendly policies of today's best businesses.

We can identify your energy waste and suggest profitable ways to reduce that waste. We have a full staff of engineers and designers; we work on all commercial and industrial processes and can help you determine a quick and profitable solution.

If you think an energy-saving/waste heat recovery program might make sense for your company, please get in touch with us and ask about our free Energy Survey and our Power Savings Management Plans.

Advantages

- Low Heat Requirements

- Flexible & Scalable up to 1MW

- Low Cost

- No Combustion

- Zero Toxic Byproducts

- Zero Emissions

- Zero Fuel Requirements

- Modular & Mobile

How it works:

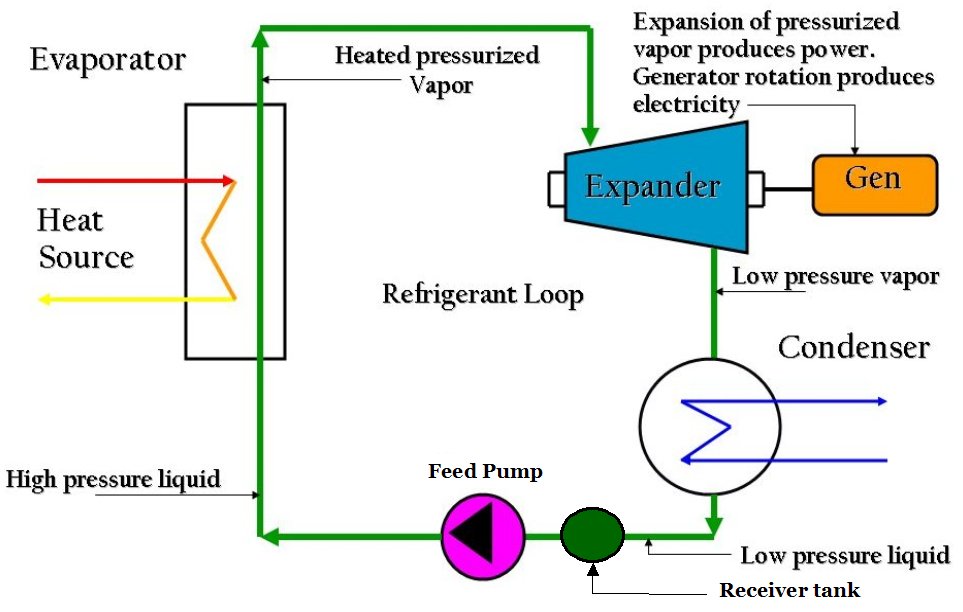

1. Waste heat from industrial and other cogeneration processes is passed through a heat exchanger (Via Liquid or Gas).

2. Heat Exchanger heats an EPA-approved working fluid driving a Low-Friction expander.

3. The expander rotates the generator producing electricity.

A waste heat recovery unit (WHRU) is an energy recovery heat exchanger that transfers heat from process outputs at high temperatures to another part of the process for some purpose, usually increased efficiency. The WHRU is a tool involved in cogeneration.

WES Industries, Inc.

Manufactures to meet all NSF, ASTM, ASME, and ANSI requirements.